Quadrant Future Tek Ltd. - IPO Note

Engineering - Rail Construction

Quadrant Future Tek Ltd. - IPO Note

Engineering - Rail Construction

Stock Info

Shareholding (Pre IPO)

Shareholding (Post IPO)

Company Description

Quadrant Future Tek Ltd. (QFTL) is a research oriented company, engaged in developing new generation Train Control and Signalling Systems under KAVACH project of the Indian Railways that offers the highest level of safety and reliability to rail passengers and also possess a Speciality cable manufacturing facility with Electron Beam Irradiation Centre. The speciality cable manufactured by the Company is used in Railways rolling stock and Naval (Defence) industry. Its facility also possesses end to end infrastructure capabilities for production of Solar & EV Cables. The Company has one facility for manufacturing, testing, researching, and developing specialty cables and also to manufacture the hardware required for Train Control & Signalling Division, which is situated at Village Basma Tehsil Banur, Dist Mohali.

Specialty Cables Division

The Company offers Speciality Cables for the industrial usage and other applications

where fire and safety, light weight and long term performance are of utmost importance.

The in-house formulated low smoke fire resistant polymers for insulation / sheath

of the cables are treated with Electron Beam radiations that enable the cross linking

of the molecules to achieve much superior mechanical and thermal properties. The

higher temperature bearing capacity enables the industry users to specify lower

cross-section conductor / cable sizes that enable significant weight reduction.

Thus, these Speciality cables are the ultimate choice for rail vehicles, trains,

naval ship vessels & submarines, electric vehicles and fuel cell electric vehicles

where weight & fire Safety are the most significant criterion for component

/ material selection.

The Speciality cable also has major application in Solar & Wind installations where thermal resistance, long term durability & extended warranties are the key factors. It has installed a 2.5 MeV Electron Beam Industrial Accelerator for cable manufacturing plant which helps it to offer Speciality cables with improved mechanical properties, abrasion and thermal resistance, flame propagation resistance and deformation resistance properties without producing heat and an increased life as compared to chemically cross linked cables. The Company is accredited with various national and international certifications namely, NQA Certification Limited and ROHS Certification Private Limited for its speciality cables division. It has a wide product portfolio which includes railways rolling stock cables, naval defence, marine cables, solar PV cables, automotive cables, and connectors & junction boxes. It also provides end to end solutions for electrical connectors and wiring harness with the complex arrangement of various wires and cables as per the demand of the client.

For the Speciality Cable division, Company had an installed capacity of 1,887.60 metric tonnes as on September 30, 2024, 1,887.60 metric tonnes as on March 31, 2024, 1,638.00 metric tonnes as on March 31, 2023 and 1,500.72 metric tonnes as on March 31, 2022, which was utilised at a capacity of 25.03% (not annualised), 49.42%, 54.26% and 57.62% respectively.

Train control & signalling division

The growing Indian landscape for railways serves as a key opportunity for the Company.

With a huge emphasis on the modernization of Railways in India and thrust on Make

in India, accompanied by ambition for high speeds trains, the requirement of Automated

Train Safety and signalling systems is inevitable. The Indian Railways plays a crucial

role in ensuring the smooth and secure operation of trains across the rail network.

For enhancing the safety standards and faster movement, Indian Railways is developing

and creating technology in areas such as signalling and telecommunication with the

installation of 'Kavach', the domestically developed Train Collision Avoidance

System, on the Indian Railway network. It is a combination of hardware equipment

and software that monitors train locations and movements. Once implemented by Indian

Railways, KAVACH will be the world's most economical automatic train collision

protection system that ensures the safety of human life and the rail infrastructure.

The company has a dedicated Railway Signalling & Embedded System Design centre for the development of Train Control Products & Solutions and is working towards the development of a Train Collision Avoidance System and Electronic Interlocking System under KAVACH as a means of Automatic Train Protection System to enable safety and capacity augmentation in Indian Railways. The company has built this indigenously developed Train Collision Avoidance System that uses radio transmission & support LTE technology meeting the Safety Critical standards as per SIL-4 requirements, interoperability with other competitors products & systems, and detect and stop a possible train collision under the KAVACH project developed by the Research Designs & Standards Organisation (RDSO) under the Ministry of Railways. They have vertically integrated manufacturing operations for the hardware and software required for Train Control and Signalling Division which allows them to manage manufacturing processes in-house, from design and development to manufacturing and delivery.

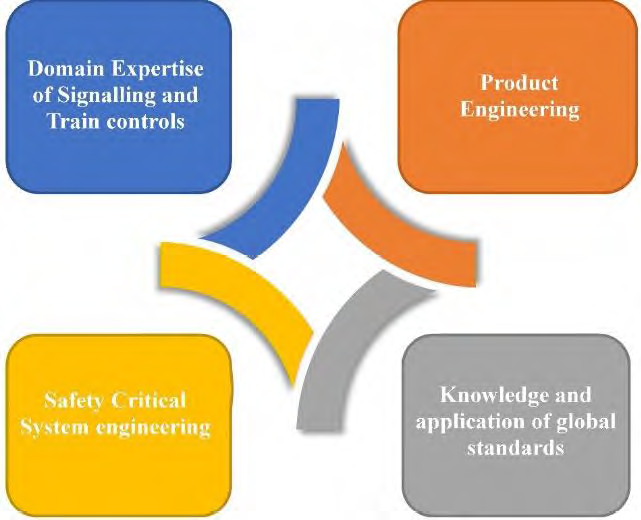

Competitive Strengths

Innovation and technological development undertaken by the Company for building

Automatic Train Protection Systems

There are four building blocks that constitute train control systems, namely:

For implementation of a TCAS system, four systems are separately installed, comprising

of on-track equipment (e.g. RFID tags), track side equipment (e.g. railway towers),

indoor equipment (e.g. station TCAS, relay, etc) and on-board equipment (i.e. Loco

TCAS, Driver Machine Interface, etc). Kavach is the first system in India that has

bought all these four systems together.

Product Engineering:

To be able to conceive and design a product, the company should have architecture

level skills, design skills, and product management. Also, product engineering should

overcome constraints related to mechanical, electrical, electronic, software, data,

communication, and logistic processes.

Safety critical system engineering:

Safety-critical systems are systems where a failure could lead to loss of life or

significant damage to property or the environment. One of the critical factors for

building train control systems is to have skill pertaining to safety-critical system

safety thinking.

Knowledge and application of global standards:

The Train Control System are designed and developed by our Company in line with

CENELEC Standards to meet SIL-4 safety specification.

In-house design and product development capabilities powering Rail Signalling

Products & Solutions

QFTL designed, developed and engineered the software for Train Collision Avoidance

System in-house with a focus on performance, reliability and autonomy and in - line

with the needs of Indian Railways. It undertakes manufacturing operations at manufacturing

facility, situated in Basma, Mohali, Punjab, with a dedicated Production floor area

of approximately 60,000 sq. ft. and is equipped with advanced equipment, modern

technology, and automation systems to manufacture the hardware required for Train

Control & Signalling Division. Their ability to drive technology and product

innovation also facilitated in-house train Collision avoidance system which they

believe is adhering to the requirement of RDSO.

With integrated operations i.e., from design and development to manufacturing, assembly and testing and to provide software solutions, it strives to be able to meet all needs to successfully provide solution for Train Control & Signalling Division under a single roof as well as control and maintain the quality of hardware thereby maintaining the overall reliability and durability of hardware.

Advanced manufacturing facilities with a diverse range of power and control cables

with focus on innovation and cost competitiveness

QFTL is one of the few manufacturers in India approved by RDSO, DGQA and Indian

register of shipping with in-house capabilities of manufacturing and supply of Single

Core / multi core Control & Power Cables, Signalling Cables for use in Railway

Coaches, Locomotives & EMU's and also for the supply of Single Core/Multi

Core, Screened/Un-Screened & Power Cables for Naval Ships. Their Railway Signalling

& Embedded System Design team and technological capabilities have helped them

in diversifying products in the speciality cables segment.

It manufactures products within manufacturing facility located at Basma, Distt. Mohali, Punjab. They have developed systems throughout production process to ensure the quality and reliability of products and meet the standards of RDSO, DGQA and Indian Register of Shipping. Their manufacturing facility is accredited with quality management system certificates for compliance with ISO 9001:2015, 14001:2015 and 9001:2015 requirements. It operates automated machines like Extruder machines of different grades for melting PVC raw material, bunching and stranding machines for processing copper wires, coiling & moulding machines for processing of various types of cables, etc. All of these require specialty formulations, which is done in-house in compounding facility. Their Speciality cables manufacturing facility has a total installed production capacity of 1,887.60 MTPA as at September 30, 2024.

The production capabilities, including the amount of capital and technology investment, 2.5 MeV Electron Beam Industrial Accelerator for cable manufacturing, operational expertise and industry knowledge accumulated to deliver products which are further enhanced with in-house research facility, coupled with RDSO, DGQA and Indian Register of Shipping constitute a high barrier to entry for other companies to emulate. They received Fresh Registration for inclusion of the name of Company in the ‘List of RDSO vendors for developmental orders for manufacture and supply of electric items QAE-M-7.1-2 (latest)’ on December 14, 2017 and it has more than six years of experience in the manufacturing of the irradiated wires and cables. The electron beam cross-linking is carried out at room temperature and with the electron–beam accelerators, the insulation materials can be cross–linked within a few seconds. The homogeneous irradiation ensures that the homogeneous cross-linking is achieved. The Electron Beam accelerator machine is operated by experienced and well trained technical personnel and thus, helps them to utilise the machine in the most efficient manner. Also, the 2.5 MeV Electron Bea Accelerator commenced operations only after complying with the stringent requirements of AERB (Atomic Energy Regulatory Board) has the continuing operations are also supervised by AERB periodically to ensure compliance with their requirements.

Global emergence of market for Speciality cables in renewable energy and electric

vehicles and supply of such Speciality cables to OEMs with high global market penetration

There is a growing thrust on adopting electric vehicles (EVs) across the globe amid

increasing carbon emissions which have serious repercussions including global warming.

Specialty power cables play an important role in the safety of new energy vehicles.

For instance, high-quality specialty power cables can ensure that the electrical

system can work properly and ensure a low failure rate, thereby reducing the risk

of accidents such as fires and explosions. Based on our deep product knowledge and

multiple usage of Speciality cables, gives us expansive insight into multiple industries,

we believe that may serve as a critical source supplier for global OEMs.

Further, India's solar energy sector has emerged as a key participant in grid-connected power generation capacity over the past decade. It contributes significantly to the government's objective of sustainable growth while emerging as a key anchor in meeting the nation's energy demands and ensuring energy security. Therefore, the specialty cable market growth is attributable to the positive outlook for the solar power segment, further accredited to government support and growing environmental consciousness. The Company has developed solar cables in line with 2pfg 1169 / N50618 requirements for captive solar projects dedicated to electric charging stations, and green hydrogen plants for the generation of green energy. They have further developed low-fire hazard, lightweight cables for electric vehicles, to cater to the transition of fossil fuel vehicles to Battery/hydrogen electric vehicles.

Peer Comparison

| Name of the company (FY24) | Revenue from operations (Rs. In cr) | ROE (%) | ROCE (%) | P/E (x) | EBITDA Margin (%) |

|---|---|---|---|---|---|

| Quadrant Future Tek Ltd. | 152.00 | 33.41% | 26.12% | 79.00 | 24.11% |

| Kernex Micro systems Ltd | 20.00 | -27.30% | -22.82% | - | -99.25% |

| HBL Power Systems Ltd | 223.00 | 25.70% | 31.75% | 61.59 | 19.76% |

| Apar Industries Ltd | 16153.00 | 26.38% | 34.87% | 49.11 | 10.00% |

| Polycab Ltd | 18039.00 | 24.20% | 30.04% | 64.85 | 15.00% |

Key Risks & Concerns

Volatility in the key raw material prices – Any significant increase in key raw material prices may have a material adverse effect on the company’s business, results of operations, financial condition, cash flows, and prospects.

Customer concentration – The Company is dependent on and derives a substantial portion of its revenue from a limited number of customers. Cancellation or orders by customers or delay or reduction in their orders could have a material adverse effect on the business, results of operations, and financial condition. Top 10 customers contribute 86% of the overall revenues during the financial year 2024.

Competitive intensity – QFTL operates in a competitive environment and an inability to compete effectively may adversely affect our results of operations, financial condition, and business prospects.

Outlook and Valuation

Quadrant Future Tek Ltd. (QFTL) is a research-oriented company, engaged in developing new-generation Train Control and Signalling Systems under the KAVACH project of the Indian Railways. It has two main segments: The Specialty Cables Division and the Train Control and Signalling Division. It also has a manufacturing facility featuring an Electron Beam Irradiation Centre. It is a technology and innovation-driven Company and its products comply with ISO / IRIS / TS standards and follow rigorous and robust Quality Management Systems for specialty cables. Further, their in-house testing facility is equipped to conduct the tests for the Train Controls and Signalling Division in adherence with most of the internationally recognized test standards, including DIN, UIC, BS, UL, CE & CENELEC Standards, and ensures that every product undergoes stringent quality tests accordingly to meet the international standards at various stages of production before its delivery. This has enabled them to develop long-term and entrenched relationships with the customers that have resulted in growth in business operations. We expect that quality management systems will enable system-driven efficiency and continue to attract higher revenues going forward for the company.

The long-term outlook for the specialty cables industry is positive on account of structural megatrends and a growing focus on domestic manufacturing and technology. Some of the key growth drivers are Government Push for Railway Infrastructure Upgradation, the Introduction of New Technologies as Control Systems in Indian Railways, Growing Capital Expenditure on Naval Defence, Expansion of Renewable Energy Plans, and Growing Demand for Electric Vehicles and Automotive.

In the interim budget of FY2024-25, the FM allocated Rs. 2.55 lakh crores to Indian Railways, a 5.8% increase. The KAVACH automatic train protection system aims to enhance safety, expanding coverage to 4,500 kilometres next year and targeting 44,000 kilometres over five years. Additional tenders for 6,000 kilometres are expected soon. We believe that competitive advantage is driven by technology and innovation-driven approach, efficiency in operations, maintaining quality control, experienced domain professionals, and design and development team for embedded systems enabling indigenously developed solutions. Additionally, the strategic MoU signed with RailTel Corp. to provide KAVACH coupled with a recent order win from Chittaranjan Locomotive Works (CLW) of Rs 978.6 cr, solidifies the company’s position as a premier Original Equipment Manufacturer (OEM). Successfully managing such a substantial order with its current resources will require diligent oversight. The company's balance sheet stands at Rs 149 crore, indicating that the issue size is double the balance sheet and nine times the equity capital, so the effective deployment of the IPO proceeds will be vital. On the valuation front, the issue is priced/ valued at 79x at post-issue based on FY24 earnings, which appears higher than some of its peers. Therefore, aggressive investors can SUBSCRIBE to the issue.

Key Information

Use of Proceeds:

The total issue size is Rs.290cr, which comprises an entire free issue of Rs.290

cr with no Offer for Sale (OFS) component. From the net proceeds of the issue, the

company will utilize Rs.149.72cr towards Funding long-term working capital requirements

of Company (Specialty Cable Division), (Rs.24.37 cr) for Capital expenditure for

development of Electronic Interlocking System, Prepayment or repayment of all or

a portion of outstanding working capital term loan availed by Company (Rs.23.62

cr) and towards General Corporate Purpose (Rs.92.29 cr).

Book running lead managers:

Sundae Capital Advisors Private Ltd

Management:

Satish Gupta (Independent Chairman), Mohit Vohra (Managing Director), Pramod Jain

(Additional Independent Director), Girish Buttan (Additional Independent Director),

Kanika Bhutani (Additional Independent Director), Amit Dhawan (Whole Time Director),

Amrit Singh Randhawa (Amrit Singh Randhawa), Rupinder Singh (Whole Time Director),

Vishesh Abrol (Whole Time Director), Vivek Abrol (Whole Time Director), Aikjot Singh

(Non - Executive Director), Rajbir Singh Randhawa (Non - Executive Director), Amit

Kumar Jain (Chief Financial Officer).

Financial Statement

Profit & Loss Statement:- (Consolidated)

| Particulars (Rs. In cr) | FY22 | FY23 | FY24 | H1FY25 |

|---|---|---|---|---|

| Revenue from operations | 104.00 | 153.00 | 152.00 | 65.00 |

| Total revenue | 104.00 | 153.00 | 152.00 | 65.00 |

| Cost of materials consumed | 89.00 | 103.00 | 93.00 | 56.00 |

| Changes in inventories | -8.50 | 7.00 | -5.00 | -14.00 |

| Employee benefit expenses | 7.00 | 5.00 | 12.00 | 12.00 |

| Other expenses | 8.00 | 11.00 | 15.00 | 11.00 |

| Total expenses | 95.00 | 126.00 | 115.00 | 64.00 |

| EBITDA | 9.50 | 26.00 | 37.00 | 0.80 |

| Depreciation expenses | 3.00 | 4.00 | 10.00 | 10.00 |

| EBIT | 6.00 | 23.00 | 26.00 | -9.00 |

| Finance costs | 3.00 | 3.00 | 4.50 | 4.00 |

| Other Income | - | - | - | - |

| PBT | 3.00 | 20.00 | 22.00 | -12.50 |

| Tax expenses | 1.00 | 6.00 | 7.00 | -0.40 |

| PAT | 2.00 | 14.00 | 15.00 | -12.00 |

| EPS (Rs.) | 0.60 | 4.60 | 4.90 | -4.00 |